Fighter jets are among the most advanced machines humans have ever built. They need to be fast, lightweight, and strong enough to survive extreme conditions. Traditionally, building these aircraft has been a long, expensive, and complex process. Every component, from engine parts to structural supports, requires precise engineering and careful assembly. However, a new technology—3D printing, also called additive manufacturing—is changing the way fighter jets are designed, built, and maintained.

With 3D printing, manufacturers can create parts faster, lighter, and more cost-effectively. This innovation is helping the aerospace industry overcome long-standing challenges in aircraft production. In this article, we’ll explore how 3D printing is applied to fighter jets, focusing on five key parts, and explain why this technology is transforming modern aviation.

What is 3D Printing?

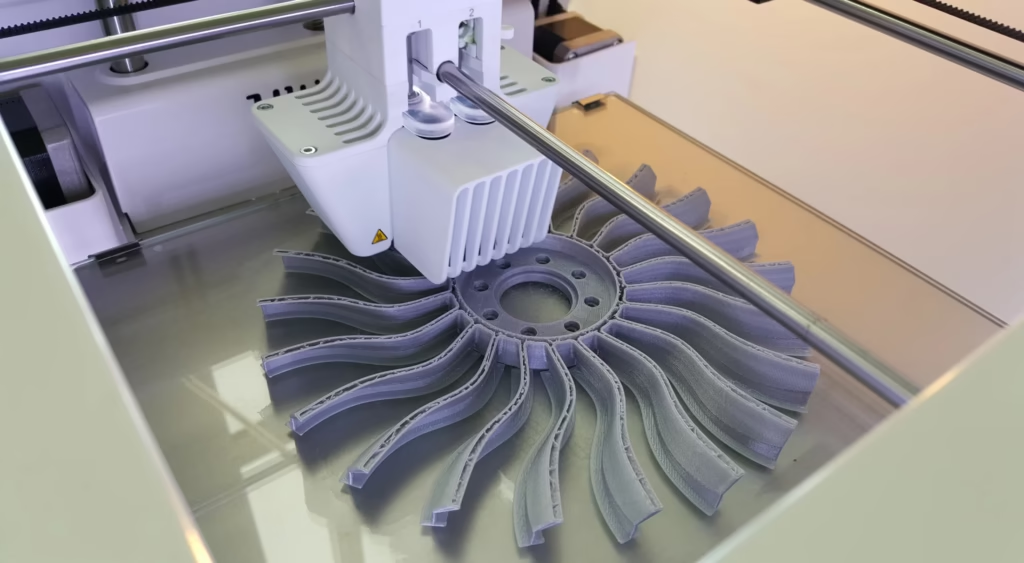

3D printing is a process of creating three-dimensional objects layer by layer from a digital design. Unlike traditional manufacturing methods that often cut or drill material to form a shape, 3D printing adds material only where it is needed, reducing waste and enabling complex designs.

In aerospace, this technology allows engineers to create intricate parts that are impossible or very difficult to produce with traditional methods. These include components with hollow structures, lightweight frameworks, or specialized cooling channels in engines.

Why 3D Printing Matters for Fighter Jets

Fighter jets require parts that are strong, light, and precise. Traditional manufacturing can take weeks or months for some components, and assembling complex parts often adds more time and cost.

Here’s why 3D printing is changing the game:

- Faster Production: Parts that once took weeks to manufacture can now be printed in days or even hours.

- Cost Savings: Less material waste and fewer production steps reduce overall costs.

- Lightweight Designs: Engineers can create complex structures that are lighter without sacrificing strength, improving fuel efficiency and agility.

- Rapid Prototyping: New designs can be tested quickly, allowing for faster innovation.

- Customizable Components: Parts can be tailored for specific missions or aircraft, increasing flexibility.

By combining speed, precision, and flexibility, 3D printing is making fighter jet production more efficient and adaptable.

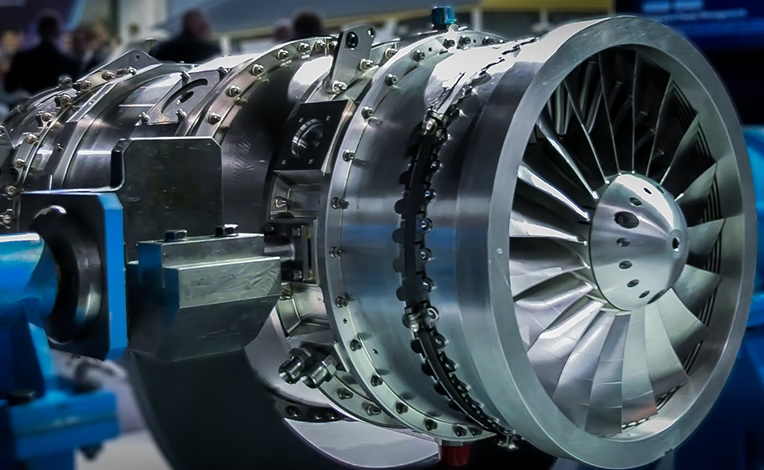

1. Engine Components

One of the most critical parts of a fighter jet is the engine. Jet engines operate under extreme temperatures and pressures and require parts that can withstand intense stress.

Traditional manufacturing struggles to produce complex shapes like turbine blades, fuel nozzles, and internal cooling channels. These shapes are crucial for engine efficiency and performance but are difficult and costly to create using conventional methods.

How 3D printing helps:

- Precision Design: 3D printing can produce turbine blades and nozzles with extremely accurate designs.

- Weight Reduction: The process allows for lightweight structures without compromising strength.

- Improved Performance: Optimized designs enhance airflow and fuel efficiency.

For example, manufacturers can now print engine fuel nozzles in a single piece with internal channels that reduce weight and improve combustion. This innovation not only boosts performance but also reduces the time and cost of engine production.

2. Structural Brackets and Supports

Fighter jets are full of support brackets that hold wiring, pipes, and critical systems. While they might seem small, these components play a vital role in the jet’s overall structure.

Traditional brackets are often heavy and complex to manufacture. With 3D printing, brackets and supports can be made lighter and stronger.

Key benefits:

- Up to 55% Lighter: Printing allows the removal of unnecessary material without weakening the part.

- Stronger Materials: Advanced 3D printing materials can withstand high stress.

- Fuel Savings: Every kilogram saved reduces fuel consumption and increases performance.

Companies like Boeing and Airbus already use 3D printed brackets and supports to reduce the weight of their aircraft, highlighting how additive manufacturing can benefit both commercial and military aviation.

3. 3D Printed Panels

The interior of a fighter jet includes panels that form the cockpit, cabin, and various compartments. Traditionally, these panels are cut, molded, and assembled, which can take a long time.

3D printing enables:

- Custom Fit Panels: Each panel can be printed to match exact dimensions.

- Faster Production: Panels can be printed quickly, reducing assembly time.

- Enhanced Comfort: Interior parts, like seats and cabin components, can be optimized for ergonomics.

For instance, Airbus uses 3D printed panels to fill gaps in cabins and shape seats, improving passenger comfort while streamlining production. The same principle applies to fighter jets, where interior parts must be both functional and lightweight.

4. Replaceable Engine Parts

Maintenance and repair are vital for keeping fighter jets operational. Over time, engine components can wear out and require replacement. Traditionally, repairing an engine can be time-consuming and expensive.

3D printing is helping by producing replaceable engine parts quickly, using recycled metal from older aircraft.

Example:

- The UK’s Tornado 2 Tempest project recycles metal from old fighter jets to print parts like fan blades and nose cones.

- These parts undergo strict safety testing and are ready for use much faster than conventionally manufactured components.

This approach reduces downtime, lowers costs, and extends the service life of aircraft. 3D printing is transforming repairs into faster, more flexible processes, ensuring fighter jets remain mission-ready.

5. Weapon System Components

Fighter jets are designed to carry advanced weaponry, and components like missile pylons and weapons mounts are critical. These parts must withstand extreme forces and maintain precision alignment.

3D printing benefits weapon system components by:

- Reducing Downtime: Parts can be produced on-site or on-demand.

- Using Advanced Materials: Titanium and other high-strength metals can be printed for durability.

- Customizing Designs: Each part can be tailored for specific aircraft or mission needs.

The Royal Air Force has already installed its first in-house 3D printed titanium part on a Typhoon fighter jet, demonstrating the reliability and effectiveness of this technology in operational scenarios.

Advantages of 3D Printing in Fighter Jets

Overall, the adoption of 3D printing in fighter jet manufacturing provides:

- Flexibility – Customizable components meet specific operational needs.

- Innovation – Complex geometries that were previously impossible are now achievable.

- Cost Efficiency – Reduced material waste and production steps save money.

- Speed – Faster manufacturing and repair keep aircraft ready for missions.

- Lightweight Designs – Weight reduction improves fuel efficiency and performance.

These advantages are why major aerospace companies and military organizations are investing heavily in additive manufacturing technology.

Challenges and Considerations

Despite its many benefits, 3D printing in aerospace comes with challenges:

- Safety and Testing – All 3D printed parts must pass rigorous quality and safety standards.

- Material Limitations – Not all metals or composites are suitable for 3D printing.

- Certification – Parts must meet aviation regulations before being used in operational aircraft.

- Technology Costs – Advanced printers and materials can be expensive, though costs are decreasing over time.

Even with these hurdles, the advantages of 3D printing far outweigh the challenges, and the technology is steadily gaining acceptance in the aerospace industry.

The Future of 3D Printing in Fighter Jets

As 3D printing technology advances, its role in fighter jet manufacturing is expected to expand:

- Entire Aircraft Components: In the future, entire sections of fighter jets may be printed rather than assembled from multiple parts.

- Advanced Materials: New alloys and composites specifically designed for 3D printing could enhance strength and durability.

- On-Demand Production: Parts may be printed as needed, reducing supply chain dependence.

- Rapid Prototyping and Testing: Designs can be tested and iterated faster, encouraging innovation.

3D printing is not just improving current aircraft—it is shaping the future of aviation, enabling faster, lighter, and more efficient fighter jets than ever before.

Conclusion

3D printing is transforming the way fighter jets are manufactured, maintained, and upgraded. From engine components to weapon system mounts, this technology allows for faster production, cost savings, and lighter, stronger designs.

As 3D printing becomes more widespread, the aerospace industry will continue to see innovations that improve performance, reduce costs, and enable rapid repairs. Safety testing and material standards remain critical, but the benefits of additive manufacturing are undeniable.

The adoption of 3D printing in fighter jets marks a new era in aerospace technology, making aircraft more efficient, flexible, and ready for the challenges of modern military operations.