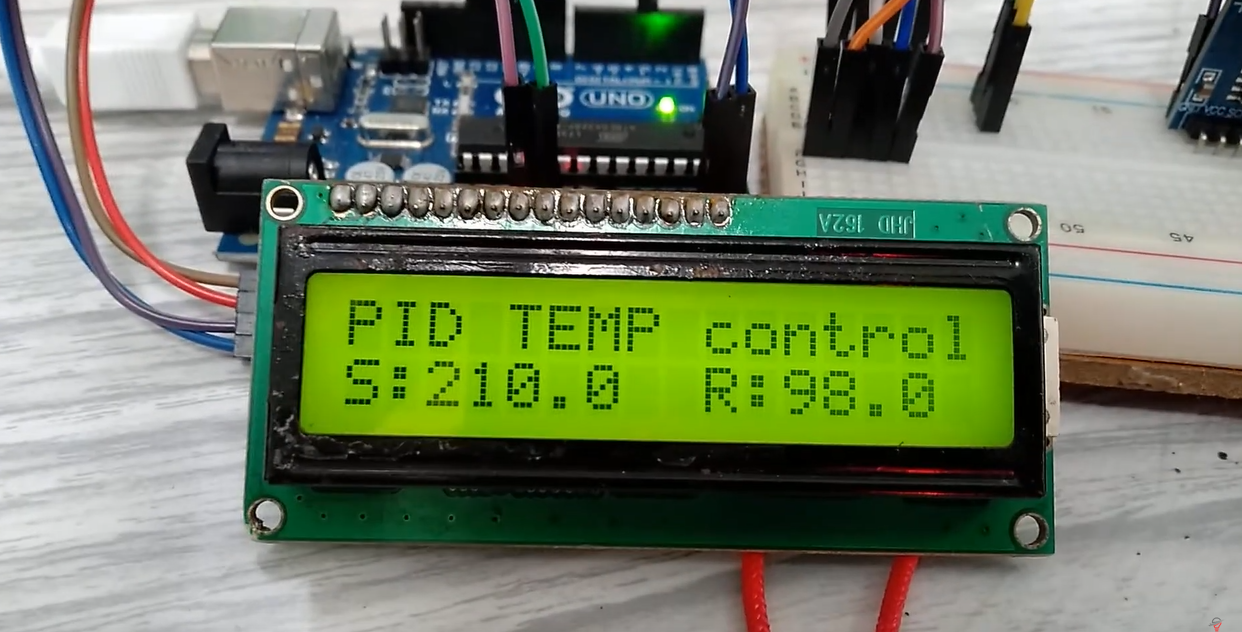

In many applications, precise temperature control is essential—whether for industrial processes, 3D printing, or even home brewing. One of the best ways to achieve accurate temperature regulation is by using a PID (Proportional-Integral-Derivative) controller. In this guide, we’ll build a DIY PID temperature control system using an Arduino, a K-Type thermocouple with a MAX6675 amplifier, and an LCD 16×2 display to monitor the temperature.

🔹 Components Required

Before we dive into the project, here’s what you’ll need:

- Arduino Board (Uno, Mega, or any compatible board)

- K-Type Thermocouple with MAX6675 Amplifier (for temperature sensing)

- 16×2 LCD Display with I2C Module (for displaying temperature)

- Relay Module (to control the heating element)

- Heating Element (such as a resistor, nichrome wire, or heater)

- Cooling Fan (optional) (for active cooling in both heating/cooling applications)

- Push Buttons or Potentiometer (for manual tuning, if desired)

- Power Supply (as per the heating element requirements)

- Connecting Wires & Breadboard

💡 Note: As an Amazon Associate, I earn from qualifying purchases. This helps me keep creating valuable content without any additional cost to you.

🔹 Understanding PID Temperature Control

PID stands for:

- Proportional (P): Corrects errors proportionally.

- Integral (I): Reduces steady-state errors.

- Derivative (D): Reacts to rapid changes.

Using the PID library in Arduino, we can fine-tune these parameters to maintain a stable temperature around the setpoint.

🔹 Wiring Diagram

Connections

K-Type Thermocouple with MAX6675 to Arduino

| MAX6675 Pin | Arduino Pin |

|---|---|

| VCC | 5V |

| GND | GND |

| SCK | D13 |

| CS | D10 |

| SO | D12 |

16×2 LCD with I2C Module to Arduino

| LCD I2C Pin | Arduino Pin |

|---|---|

| VCC | 5V |

| GND | GND |

| SDA | A4 |

| SCL | A5 |

Relay Module to Arduino

| Relay Pin | Arduino Pin |

|---|---|

| VCC | 5V |

| GND | GND |

| IN | D9 |

🔹 The heating element is connected to Relay COM (Common) and NO (Normally Open) terminals, while the power source is linked accordingly.

🔹 Arduino Code

We’ll use the PID Library and MAX6675 Library to handle temperature control.

Install Libraries

Before uploading the code, install the following libraries in the Arduino IDE:

- PID Library (

PID_v1.h) – for PID control. - MAX6675 Library (

max6675.h) – to read the thermocouple. - LiquidCrystal_I2C – for LCD display control.

Complete Code

#include <Wire.h>

#include <LiquidCrystal_I2C.h>

#include <max6675.h>

#include <PID_v1.h>

// LCD setup

LiquidCrystal_I2C lcd(0x27, 16, 2);

// MAX6675 setup

#define SCK 13

#define CS 10

#define SO 12

MAX6675 thermocouple(SO, SCK, CS);

// PID Variables

double setpoint = 100.0; // Target Temperature

double input, output;

double Kp = 2.0, Ki = 5.0, Kd = 1.0; // Tune these values

// Relay control

int relayPin = 9;

PID myPID(&input, &output, &setpoint, Kp, Ki, Kd, DIRECT);

void setup() {

Serial.begin(9600);

lcd.begin(16, 2);

lcd.backlight();

pinMode(relayPin, OUTPUT);

digitalWrite(relayPin, LOW);

myPID.SetMode(AUTOMATIC);

}

void loop() {

// Read temperature from the thermocouple

input = thermocouple.readCelsius();

// Compute PID output

myPID.Compute();

// Control relay based on PID output

if (output > 50) {

digitalWrite(relayPin, HIGH);

} else {

digitalWrite(relayPin, LOW);

}

// Display on LCD

lcd.setCursor(0, 0);

lcd.print("Temp: ");

lcd.print(input);

lcd.print("C ");

lcd.setCursor(0, 1);

lcd.print("Set: ");

lcd.print(setpoint);

lcd.print("C ");

Serial.print("Temperature: ");

Serial.print(input);

Serial.println(" °C");

delay(1000); // Update every second

}

Arduino Code for PID Temperature Control and Display

//LCD config (i2c LCD screen, you need to install the LiquidCrystal_I2C if you don't have it )

#include <Wire.h>

#include <LiquidCrystal_I2C.h>

LiquidCrystal_I2C lcd(0x3F,16,2); //sometimes the adress is not 0x3f. Change to 0x27 if it dosn't work.

/* i2c LCD Module ==> Arduino

* SCL ==> A5

* SDA ==> A4

* Vcc ==> Vcc (5v)

* Gnd ==> Gnd */

#include <SPI.h>

//We define the SPI pìns

#define MAX6675_CS 10

#define MAX6675_SO 12

#define MAX6675_SCK 13

//Pins

int PWM_pin = 3;

//Variables

float temperature_read = 0.0;

float set_temperature = 210;

float PID_error = 0;

float previous_error = 0;

float elapsedTime, Time, timePrev;

int PID_value = 0;

//PID constants

int kp = 9.1; int ki = 0.3; int kd = 1.8;

//int kp = 9.1; int ki = 0; int kd = 0;

int PID_p = 0; int PID_i = 0; int PID_d = 0;

void setup() {

pinMode(PWM_pin,OUTPUT);

TCCR2B = TCCR2B & B11111000 | 0x03; // pin 3 and 11 PWM frequency of 980.39 Hz

Time = millis();

lcd.init();

lcd.backlight();

}

void loop() {

// First we read the real value of temperature

temperature_read = readThermocouple();

//Next we calculate the error between the setpoint and the real value

PID_error = set_temperature - temperature_read;

//Calculate the P value

PID_p = kp * PID_error;

//Calculate the I value in a range on +-3

if(-3 < PID_error <3)

{

PID_i = PID_i + (ki * PID_error);

}

//For derivative we need real time to calculate speed change rate

timePrev = Time; // the previous time is stored before the actual time read

Time = millis(); // actual time read

elapsedTime = (Time - timePrev) / 1000;

//Now we can calculate the D calue

PID_d = kd*((PID_error - previous_error)/elapsedTime);

//Final total PID value is the sum of P + I + D

PID_value = PID_p + PID_i + PID_d;

//We define PWM range between 0 and 255

if(PID_value < 0)

{ PID_value = 0; }

if(PID_value > 255)

{ PID_value = 255; }

//Now we can write the PWM signal to the mosfet on digital pin D3

analogWrite(PWM_pin,255-PID_value);

previous_error = PID_error; //Remember to store the previous error for next loop.

delay(300);

//lcd.clear();

lcd.setCursor(0,0);

lcd.print("PID TEMP control");

lcd.setCursor(0,1);

lcd.print("S:");

lcd.setCursor(2,1);

lcd.print(set_temperature,1);

lcd.setCursor(9,1);

lcd.print("R:");

lcd.setCursor(11,1);

lcd.print(temperature_read,1);

}

double readThermocouple() {

uint16_t v;

pinMode(MAX6675_CS, OUTPUT);

pinMode(MAX6675_SO, INPUT);

pinMode(MAX6675_SCK, OUTPUT);

digitalWrite(MAX6675_CS, LOW);

delay(1);

// Read in 16 bits,

// 15 = 0 always

// 14..2 = 0.25 degree counts MSB First

// 2 = 1 if thermocouple is open circuit

// 1..0 = uninteresting status

v = shiftIn(MAX6675_SO, MAX6675_SCK, MSBFIRST);

v <<= 8;

v |= shiftIn(MAX6675_SO, MAX6675_SCK, MSBFIRST);

digitalWrite(MAX6675_CS, HIGH);

if (v & 0x4)

{

// Bit 2 indicates if the thermocouple is disconnected

return NAN;

}

// The lower three bits (0,1,2) are discarded status bits

v >>= 3;

// The remaining bits are the number of 0.25 degree (C) counts

return v*0.25;

}

🔹 How It Works

- The thermocouple measures the temperature.

- The MAX6675 module sends temperature data to the Arduino.

- The PID algorithm processes the data and adjusts the heating element accordingly.

- The relay module controls the heater based on the PID output.

- The LCD display shows the current temperature and the target setpoint.

🔹 Tuning the PID Controller

To achieve stable temperature control, you’ll need to tune the PID parameters (Kp, Ki, Kd). Here’s how:

- Start with Kp (proportional gain). Increase it until the system reacts quickly but doesn’t overshoot too much.

- Gradually adjust Ki to minimize steady-state error.

- If temperature fluctuations occur, fine-tune Kd to reduce oscillations.

📌 Tip: If you are not using LCD for display, use the

Serial Monitorto observe temperature changes and adjust PID values accordingly.

🔹 Applications of PID Temperature Control

- 3D Printing – Maintain consistent extrusion temperature.

- Reflow Ovens – For precise PCB soldering.

- Incubators – To control temperature for hatching eggs or lab experiments.

- Home Brewing – For fermenting or distilling at exact temperatures.

- Industrial Processing – Ensuring stable thermal conditions in manufacturing.

🔹 Conclusion

In this project, we implemented a PID-based temperature control system using an Arduino, a K-Type thermocouple with MAX6675, and an LCD 16×2 display. This method allows for precise and automated temperature regulation, making it useful for a wide range of applications.

Next Steps: Try integrating buttons or a rotary encoder to adjust the temperature setpoint dynamically!

Have questions or ideas for improvement? Drop them in the comments below! 🚀

Hi, good job, i want use this sketch for my oven pizza but i have 2 resistance (up and down). So i need control 2 pid (two max6675) contemporany. How i can make?

Can you share more detail about your project?

I make a oven for pizza. This oven have two resistance (One on the top and second on the floor). I have to check two different zones. The first resistor (top) heats the whole chamber, while the second one (floor)heats the base. So the two resistors work with different temperatures.

I read that the max6675 can work with others, having in common GND, VCC,SCK,SO, while the CS pins define the reading inputs of the individual max6675 (resistor1 and 2). what I ask is how to have on the display setpoint1,read1 to relay1, and setpoint2,read2 to relay2.

Hi EnzoFra!

You are working on an interesting projects, I would love to help you make your project successful. As per your information, I understand that you want to know how to make Arduino code for obtaining values from each max6675 and then displaying them on LCD.

As per the detail you provided I can say that you’re absolutely right in your understanding — the MAX6675 thermocouple modules can share the same GND, VCC, SCK, and SO lines, while each module needs a unique CS (chip select) pin to communicate independently with the Arduino.

What to do:

Add-

A second thermocouple (MAX6675) with its own CS (chip select) pin.

A second set of PID variables.

LCD display logic to show two temperature readings and setpoints.

The sketch given below is a sample sketch, you should include and modify the syntax as per the libraries you are using for LCD, PID and MAX6675. I hope the following code will help you to understand the process:

***************************

#include

#include

LiquidCrystal_I2C lcd(0x3F, 16, 2); // Try 0x27 if 0x3F doesn’t work

#include

// SPI shared pins

#define MAX6675_SO 12

#define MAX6675_SCK 13

// Chip Select for each thermocouple

#define MAX6675_CS1 10 // Top zone

#define MAX6675_CS2 9 // Bottom zone

// Output PWM pins

int PWM_pin1 = 3; // Top heater

int PWM_pin2 = 5; // Bottom heater

// Setpoints

float set_temperature1 = 220; // Top

float set_temperature2 = 200; // Bottom

// Temperature readings

float temp1 = 0.0, temp2 = 0.0;

// PID variables for zone 1

float error1, prev_error1 = 0, elapsedTime, Time, timePrev;

int kp1 = 9, ki1 = 1, kd1 = 2;

float PID_p1, PID_i1 = 0, PID_d1;

int PID_value1 = 0;

// PID variables for zone 2

float error2, prev_error2 = 0;

int kp2 = 10, ki2 = 1, kd2 = 3;

float PID_p2, PID_i2 = 0, PID_d2;

int PID_value2 = 0;

void setup() {

pinMode(PWM_pin1, OUTPUT);

pinMode(PWM_pin2, OUTPUT);

Time = millis();

lcd.init();

lcd.backlight();

// Optional: Set PWM frequency

TCCR2B = TCCR2B & B11111000 | 0x03; // PWM pin 3

TCCR0B = TCCR0B & B11111000 | 0x03; // PWM pin 5

}

void loop() {

timePrev = Time;

Time = millis();

elapsedTime = (Time – timePrev) / 1000.0;

// Read temperatures

temp1 = readThermocouple(MAX6675_CS1);

temp2 = readThermocouple(MAX6675_CS2);

// — PID for Zone 1 —

error1 = set_temperature1 – temp1;

PID_p1 = kp1 * error1;

if (-3 < error1 && error1 < 3) PID_i1 += ki1 * error1; PID_d1 = kd1 * (error1 - prev_error1) / elapsedTime; PID_value1 = PID_p1 + PID_i1 + PID_d1; PID_value1 = constrain(PID_value1, 0, 255); analogWrite(PWM_pin1, 255 - PID_value1); prev_error1 = error1; // --- PID for Zone 2 --- error2 = set_temperature2 - temp2; PID_p2 = kp2 * error2; if (-3 < error2 && error2 < 3) PID_i2 += ki2 * error2; PID_d2 = kd2 * (error2 - prev_error2) / elapsedTime; PID_value2 = PID_p2 + PID_i2 + PID_d2; PID_value2 = constrain(PID_value2, 0, 255); analogWrite(PWM_pin2, 255 - PID_value2); prev_error2 = error2; // --- Display --- lcd.clear(); lcd.setCursor(0, 0); lcd.print("T1:"); lcd.print(temp1, 0); lcd.print("/"); lcd.print(set_temperature1, 0); lcd.setCursor(0, 1); lcd.print("T2:"); lcd.print(temp2, 0); lcd.print("/"); lcd.print(set_temperature2, 0); delay(500); } double readThermocouple(int CS_pin) { uint16_t v; pinMode(CS_pin, OUTPUT); pinMode(MAX6675_SO, INPUT); pinMode(MAX6675_SCK, OUTPUT); digitalWrite(CS_pin, LOW); delayMicroseconds(10); v = shiftIn(MAX6675_SO, MAX6675_SCK, MSBFIRST); v <<= 8; v |= shiftIn(MAX6675_SO, MAX6675_SCK, MSBFIRST); digitalWrite(CS_pin, HIGH); if (v & 0x4) return NAN; v >>= 3;

return v * 0.25;

}

************************

if you need further help, please do not hesitate to ask agin.

//LCD config (i2c LCD screen, you need to install the LiquidCrystal_I2C if you don’t have it )

#include

#include

LiquidCrystal_I2C lcd(0x3F,16,2); //sometimes the adress is not 0x3f. Change to 0x27 if it dosn’t work.

/* i2c LCD Module ==> Arduino

* SCL ==> A5

* SDA ==> A4

* Vcc ==> Vcc (5v)

* Gnd ==> Gnd */

#include

//We define the SPI pìns

#define MAX6675_SO 12

#define MAX6675_SCK 13

#define MAX6675_CS1 10 // Top zone

#define MAX6675_CS2 9 // Bottom zone

// Output PWM pins

int PWM_pin1 = 3; // Top heater

int PWM_pin2 = 5; // Bottom heater

// Setpoints

float set_temperature1 = 220; // Top

float set_temperature2 = 200; // Bottom

// Temperature readings

float temp1 = 0.0, temp2 = 0.0;

// PID variables for zone 1

float error1, prev_error1 = 0, elapsedTime, Time, timePrev;

int kp1 = 9, ki1 = 1, kd1 = 2;

float PID_p1, PID_i1 = 0, PID_d1;

int PID_value1 = 0;

// PID variables for zone 2

float error2, prev_error2 = 0; elapsedTime, Time, timePrev;

int kp2 = 10, ki2 = 1, kd2 = 3;

float PID_p2, PID_i2 = 0, PID_d2;

int PID_value2 = 0;

void setup() {

pinMode(PWM_pin1, OUTPUT);

pinMode(PWM_pin2, OUTPUT);

TCCR2B = TCCR2B & B11111000 | 0x03; // pin 3 and 11 PWM frequency of 980.39 Hz

Time = millis();

lcd.init();

lcd.backlight();

}

void loop() {

timePrev = Time;

Time = millis();

elapsedTime = (Time – timePrev) / 1000.0;

// Read temperatures

temp1 = readThermocouple(MAX6675_CS1);

temp2 = readThermocouple(MAX6675_CS2);

— PID for Zone 1 —

error1

//= set_temperature1 – temp1;

PID_p1 = kp1 * error1;

if (-3 < error1 && error1 < 3) PID_i1 += ki1 * error1; PID_d1 = kd1 * (error1 – prev_error1) / elapsedTime; PID_value1 = PID_p1 + PID_i1 + PID_d1; PID_value1 = constrain(PID_value1, 0, 255); analogWrite(PWM_pin1, 255 – PID_value1); prev_error1 = error1; // — PID for Zone 2 — error2 = set_temperature2 – temp2; PID_p2 = kp2 * error2; if (-3 < error2 && error2 < 3) PID_i2 += ki2 * error2; PID_d2 = kd2 * (error2 – prev_error2) / elapsedTime; PID_value2 = PID_p2 + PID_i2 + PID_d2; PID_value2 = constrain(PID_value2, 0, 255); analogWrite(PWM_pin2, 255 – PID_value2); prev_error2 = error2; // — Display — lcd.clear(); lcd.setCursor(0, 0); lcd.print("T1:"); lcd.print(temp1, 0); lcd.print("/"); lcd.print(set_temperature1, 0); lcd.setCursor(0, 1); lcd.print("T2:"); lcd.print(temp2, 0); lcd.print("/"); lcd.print(set_temperature2, 0); delay(500); } double readThermocouple(int CS_pin) { uint16_t v; pinMode(CS_pin, OUTPUT); pinMode(MAX6675_SO, INPUT); pinMode(MAX6675_SCK, OUTPUT); digitalWrite(CS_pin, LOW); delayMicroseconds(10); v = shiftIn(MAX6675_SO, MAX6675_SCK, MSBFIRST); v <>= 3;

return v * 0.25;

— PID for Zone 2 —

error2

//= set_temperature2 – temp2;

PID_p2 = kp2 * error2;

if (-3 < error1 && error1 < 3) PID_i2 += ki2 * error2; PID_d2 = kd2 * (error2 – prev_error2) / elapsedTime; PID_value2 = PID_p2 + PID_i2 + PID_d2; PID_value2 = constrain(PID_value2, 0, 255); analogWrite(PWM_pin1, 255 – PID_value1); prev_error1 = error1; // — PID for Zone 2 — error2 = set_temperature2 – temp2; PID_p2 = kp2 * error2; if (-3 < error2 && error2 < 3) PID_i2 += ki2 * error2; PID_d2 = kd2 * (error2 – prev_error2) / elapsedTime; PID_value2 = PID_p2 + PID_i2 + PID_d2; PID_value2 = constrain(PID_value2, 0, 255); analogWrite(PWM_pin2, 255 – PID_value2); prev_error2 = error2; // — Display — lcd.clear(); lcd.setCursor(0, 0); lcd.print("T1:"); lcd.print(temp1, 0); lcd.print("/"); lcd.print(set_temperature1, 0); lcd.setCursor(0, 1); lcd.print("T2:"); lcd.print(temp2, 0); lcd.print("/"); lcd.print(set_temperature2, 0); delay(500); } double readThermocouple(int CS_pin) { uint16_t v; pinMode(CS_pin, OUTPUT); pinMode(MAX6675_SO, INPUT); pinMode(MAX6675_SCK, OUTPUT); digitalWrite(CS_pin, LOW); delayMicroseconds(10); v = shiftIn(MAX6675_SO, MAX6675_SCK, MSBFIRST); v <>= 3;

return v * 0.25;

}

//We define PWM range between 0 and 255

if(PID_value 255)

{ PID_value = 255; }

//Now we can write the PWM signal to the mosfet on digital pin D3

analogWrite(PWM_pin,255-PID_value);

previous_error = PID_error; //Remember to store the previous error for next loop.

delay(300);

//lcd.clear();

lcd.setCursor(0,0);

lcd.print(“S1:”);

lcd.setCursor(0,2);

lcd.print(set_temperature_1);

lcd.setCursor(2,0);

lcd.print(“R1:”);

lcd.setCursor(2,2);

lcd.print(temperature_read_1);

lcd.setCursor(0,9);

lcd.print(“S2:”);

lcd.setCursor(0,11);

lcd.print(set_temperature_2);

lcd.setCursor(2,9);

lcd.print(“R2:”);

lcd.setCursor(2,11);

lcd.print(temperature_read_2);

}

double readThermocouple() {

uint16_t v;

pinMode(MAX6675_CS, OUTPUT);

pinMode(MAX6675_SO, INPUT);

pinMode(MAX6675_SCK, OUTPUT);

digitalWrite(MAX6675_CS, LOW);

delay(1);

// Read in 16 bits,

// 15 = 0 always

// 14..2 = 0.25 degree counts MSB First

// 2 = 1 if thermocouple is open circuit

// 1..0 = uninteresting status

v = shiftIn(MAX6675_SO, MAX6675_SCK, MSBFIRST);

v <>= 3;

// The remaining bits are the number of 0.25 degree (C) counts

return v*0.25;

}

hi, tankyou so much , i try to insert your suggestion but have one error on void loop

void loop() {

timePrev = Time;

Time = millis();

elapsedTime = (Time – timePrev) / 1000.0;

this is the final sketch with your modify but i have the error to line ‘timePrev’

//LCD config (i2c LCD screen, you need to install the LiquidCrystal_I2C if you don’t have it )

#include

#include

LiquidCrystal_I2C lcd(0x3F,16,2); //sometimes the adress is not 0x3f. Change to 0x27 if it dosn’t work.

/* i2c LCD Module ==> Arduino

* SCL ==> A5

* SDA ==> A4

* Vcc ==> Vcc (5v)

* Gnd ==> Gnd */

#include

//We define the SPI pìns

#define MAX6675_SO 12

#define MAX6675_SCK 13

#define MAX6675_CS1 10 // Top zone

#define MAX6675_CS2 9 // Bottom zone

// Output PWM pins

int PWM_pin1 = 3; // Top heater

int PWM_pin2 = 5; // Bottom heater

// Setpoints

float set_temperature1 = 220; // Top

float set_temperature2 = 200; // Bottom

// Temperature readings

float temp1 = 0.0, temp2 = 0.0;

// PID variables for zone 1

float error1, prev_error1 = 0, elapsedTime, Time, timePrev;

int kp1 = 9, ki1 = 1, kd1 = 2;

float PID_p1, PID_i1 = 0, PID_d1;

int PID_value1 = 0;

// PID variables for zone 2

float error2, prev_error2 = 0; elapsedTime, Time, timePrev;

int kp2 = 10, ki2 = 1, kd2 = 3;

float PID_p2, PID_i2 = 0, PID_d2;

int PID_value2 = 0;

void setup() {

pinMode(PWM_pin1, OUTPUT);

pinMode(PWM_pin2, OUTPUT);

TCCR2B = TCCR2B & B11111000 | 0x03; // pin 3 and 11 PWM frequency of 980.39 Hz

Time = millis();

lcd.init();

lcd.backlight();

}

void loop() {

timePrev = Time;

Time = millis();

elapsedTime = (Time – timePrev) / 1000.0;

temp1 = readThermocouple(MAX6675_CS1);

temp2 = readThermocouple(MAX6675_CS2);

// — PID for Zone 1 —

error1 = set_temperature1 – temp1;

PID_p1 = kp1 * error1;

if (-3 < error1 && error1 < 3) PID_i1 += ki1 * error1;

PID_d1 = kd1 * (error1 – prev_error1) / elapsedTime;

PID_value1 = PID_p1 + PID_i1 + PID_d1;

PID_value1 = constrain(PID_value1, 0, 255);

analogWrite(PWM_pin1, 255 – PID_value1);

prev_error1 = error1;

// — PID for Zone 2 —

error2 = set_temperature2 – temp2; PID_p2 = kp2 * error2;

if (-3 < error2 && error2 < 3) PID_i2 += ki2 * error2;

PID_d2 = kd2 * (error2 – prev_error2) / elapsedTime;

PID_value2 = PID_p2 + PID_i2 + PID_d2;

PID_value2 = constrain(PID_value2, 0, 255);

analogWrite(PWM_pin2, 255 – PID_value2);

prev_error2 = error2;

}

//We define PWM range between 0 and 255

if(PID_value 255)

{ PID_value = 255; }

//Now we can write the PWM signal to the mosfet on digital pin D3

analogWrite(PWM_pin,255-PID_value);

previous_error = PID_error; //Remember to store the previous error for next loop.

delay(300);

lcd.clear();

lcd.setCursor(0,0);

lcd.print(“T1:”);

lcd.print(temp1, 0);

lcd.print(“/”);

lcd.print(set_temperature1, 0);

lcd.setCursor(0, 1);

lcd.print(“T2:”);

lcd.print(temp2, 0);

lcd.print(“/”);

lcd.print(set_temperature2, 0);

delay(500);

}

double readThermocouple(int CS_pin) { uint16_t v;

pinMode(CS_pin, OUTPUT);

pinMode(MAX6675_SO, INPUT);

pinMode(MAX6675_SCK, OUTPUT);

digitalWrite(CS_pin, LOW);

delayMicroseconds(10);

v = shiftIn(MAX6675_SO, MAX6675_SCK, MSBFIRST);

v <>= 3;

return v * 0.25;

}

}

Please add library or file name after #include

I just provided you a sample code. You should modify it according to your libraries. syntax should be as per the libraries you are using. Libraries for SPI, LCD, PID, and MAX6675.

thanks for the help Admin, i think i replaced everything correctly but i’m stuck on the “elapsedTime” line.

Can you share your error message?

Hi, i define pins input ( #define MAX6675_CS1 10 // read Top zone and #define MAX6675_CS2 9 // read Bottom zone ). but in void loop when i write ( temp1 = readThermocouple(MAX6675_CS1) and temp2 = readThermocouple(MAX6675_CS2) ).. give me error “Compilation error: too many arguments to function ‘double readThermocouple()’ “.

If i write only ( temp1 = readThermocouple(); and

temp2 = readThermocouple(); its all ok….but i know that in this case don’t read the singolar module..