The construction world is on the brink of a revolution. Picture entire homes being printed — layer by layer — in a matter of days. This isn’t just fantasy; 3D printing is reshaping the construction industry, with the global market projected to grow at a staggering 95.5% CAGR by 2030 (Yahoo Finance).

In this blog, we’ll break down how 3D printing works in construction, why it’s causing a stir, what’s already being built, and where the technology still needs to catch up. Whether you’re a tech enthusiast, architect, or curious reader — this is the future of building.

Introduction

Imagine a home being “printed” layer by layer, rather than built brick by brick. That’s not sci-fi anymore — 3D printing is fast becoming a real force in construction. According to a recent report, the market for 3D printing in construction is expected to grow at an astonishing 95.5% CAGR by 2030. Yahoo Finance

In this post, I’ll break down how 3D printing is changing construction, why it’s gaining momentum, and what challenges still lie ahead.

What Exactly Is 3D Printing in Construction?

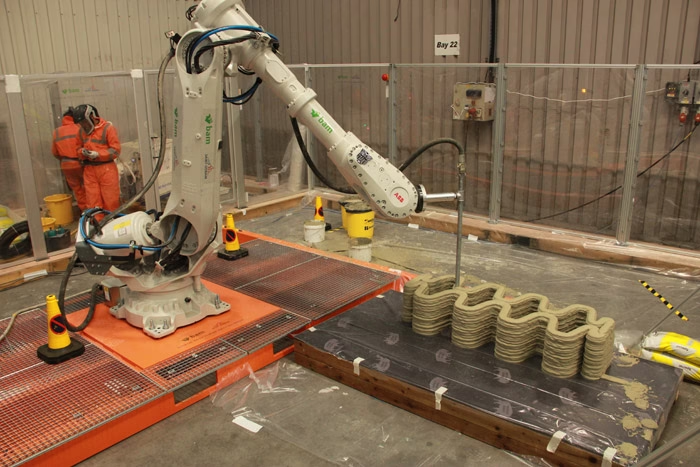

In simple terms, construction 3D printing (also called “additive construction”) builds structures by depositing material (often a special concrete mixture) layer by layer under computer control. Wikipedia Yahoo Finance

Key features:

- No traditional formwork (molds) needed, or greatly reduced.

- Ability to print walls, partitions, and even entire houses in modular sections.

- Use of robotics and automated systems to control placement and speed.

Why the Buzz? Key Benefits of 3D Printing in Construction

Here are the main advantages driving interest:

| Benefit | What It Means in Practice |

|---|---|

| Speed | Buildings or parts can be printed much faster than conventional methods. (Yahoo Finance) |

| Reduced Material Waste | Only the required material is deposited, cutting off-cuts and excess. (Yahoo Finance) |

| Cost Savings (Labor & Materials) | Lower labor costs because much of the process is automated. (Yahoo Finance) |

| Design Freedom | Complex curves, organic shapes, and custom geometries are more feasible. (Yahoo Finance) |

| Sustainability Potential | With optimized material mixes, lower waste, and energy-efficient designs, it can be greener. (Yahoo Finance) |

Because of these benefits, forecasts suggest the 3D printing in construction market could expand from billions today to over USD 100+ billion in the coming years. Yahoo Finance

Real-World Use Cases & Notable Projects

Here are some inspiring examples showing what’s already happening:

- XtreeE & other firms have experimented with printed concrete structures like inspection chambers and public infrastructure. Wikipedia Yahoo Finance

- Tecla House (Italy): A fully 3D-printed clay house built using locally sourced earth and sustainable methods. Wikipedia

- Companies like Apis Cor, Winsun are early movers in printed housing. Yahoo Finance

These projects show that the technology is not just theoretical — it’s being tested and refined in the real world.

Challenges and Bottlenecks

However, it’s not all smooth sailing. Several obstacles slow down mass adoption:

- Structural Strength & Reinforcement

Printed concrete often lacks the tensile strength of traditional reinforced concrete. Integrating steel bars or meshes within printed layers or using fiber reinforcement is still complex. Wikipedia+1 - Material Mix & Technology Optimization

Finding the right concrete/mortar mix that cures fast, is printable, and meets structural and durability requirements is still under research. Yahoo Finance - Scalability & Size Limits Large buildings or multi-story structures present challenges in stability, printing speed, and logistics.

- Regulation, Codes & Standards Building codes, safety standards, and local regulations aren’t fully adapted to 3D printed structures in many regions.

- High Initial Costs Robotic printers, software, and setup are expensive upfront. Smaller builders may find it hard to invest.

What’s Next: The Future Outlook

Despite challenges, the outlook is promising:

- Some forecasts expect 3D printing in construction to reach USD 100+ billion in market size. Yahoo Finance

- Greater integration of robotics + AI for autonomous construction sites.

- Hybrid approaches mixing traditional building and 3D printing (e.g. printing walls, and using conventional roofs)

- New materials (e.g. bio-concretes, fiber-reinforced composites) will expand possibilities.

- Emerging regulations and standards to validate printed structures.