3D printing has transformed how prototypes and functional parts are manufactured, but one challenge still persists—surface finish. Even with fine layer heights, FDM/FFF printed parts often exhibit visible layer lines due to the staircase effect inherent to layer-by-layer deposition. This is where 3D print vapor smoothing emerges as a powerful post-processing technique.

Vapor smoothing 3D printing uses controlled chemical vapors to partially dissolve the outer surface of thermoplastic prints. As the polymer chains reflow, surface irregularities are reduced, producing parts with a glossy, injection-mold-like appearance. Beyond aesthetics, research shows that vapor smoothing can significantly reduce surface roughness, seal micro-porosity, and in some cases even improve mechanical performance.

Among all methods, acetone vapor smoothing—especially for ABS—has gained widespread attention due to its effectiveness, low cost, and strong industrial relevance. However, vapor smoothing is not without risks. Improper handling of solvents can lead to health hazards, dimensional inaccuracies, and safety concerns.

This article explains what vapor smoothing is, how it works, which materials are suitable, safety guidelines, cost considerations, and when to choose a professional vapor smoothing service—all backed by authentic research data and experimental studies.

What Is 3D Print Vapor Smoothing?

3D print vapor smoothing is a chemical post-processing technique used to improve the surface quality of thermoplastic 3D-printed parts. Instead of mechanically removing layer lines through sanding or polishing, vapor smoothing exposes the printed object to solvent vapors that chemically interact with the polymer surface.

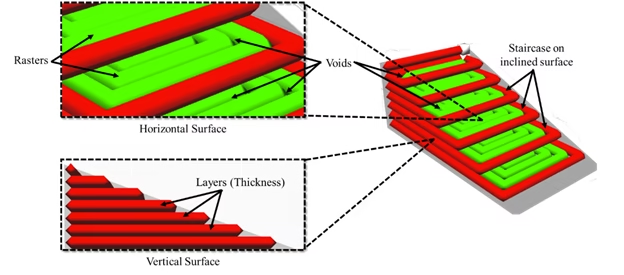

From a technical perspective, vapor smoothing relies on controlled polymer surface dissolution. When a compatible solvent vapor contacts the printed surface, it softens the outermost polymer layers. This causes material flow across adjacent layers, filling micro-gaps, other common surface issues in FDM parts and reducing the staircase effect created during fused filament fabrication (FFF) or fused deposition modeling (FDM).

Layer lines exist because FDM printers deposit molten filament in discrete layers. Even at small layer heights, the contour approximation of curved surfaces results in visible ridges. Apart from layer height and staircase effect, surface quality is affected by various reasons such as – stringing, top layer defects, heating issue, filament extrusion problems, etc. Vapor smoothing mitigates this by allowing polymer chains to rearrange and fuse across layer boundaries, producing a smoother surface topology .

This process is widely used in:

- Functional prototypes

- Medical and laboratory components

- Fluid-handling parts

- Consumer electronics housings

- Automotive interior components

Because of its ability to enhance both appearance and performance, vapor smoothing has become a standard industrial finishing method for certain polymers.

How Vapor Smoothing Works in 3D Printing

Chemical Interaction With Thermoplastics

Vapor smoothing depends on the solubility relationship between the solvent and the polymer. For example, acetone is an effective solvent for ABS because it interacts strongly with the butadiene phase of the polymer. When exposed to acetone vapor, the ABS surface partially dissolves, allowing polymer chains to mobilize and flow .

This interaction is limited to the surface, provided exposure time and solvent concentration are controlled.

Surface Reflow and Layer Fusion

As the polymer surface softens:

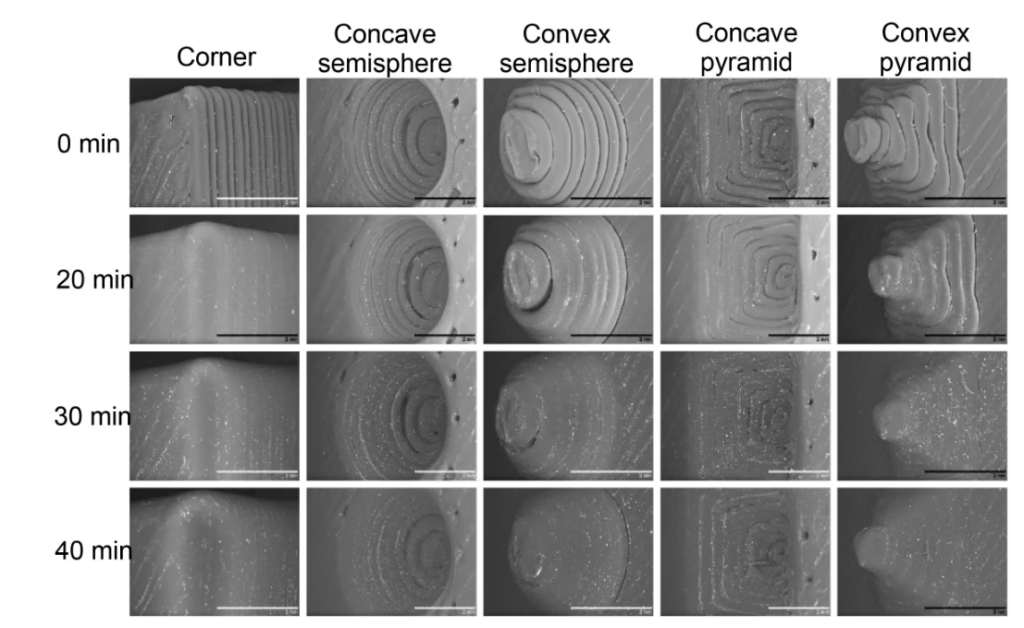

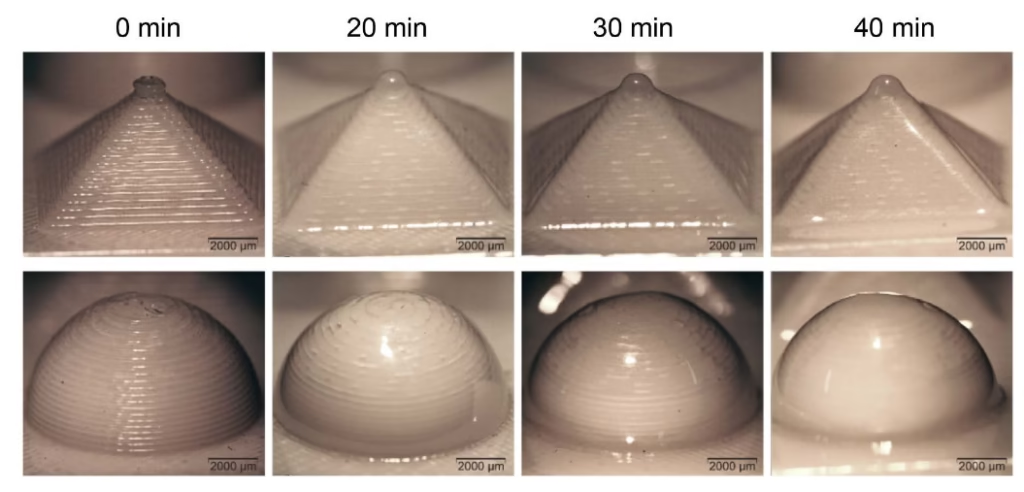

- Surface peaks collapse into valleys (as shown in above figure)

- Micro-voids between layers are filled

- Staircase artifacts are reduced

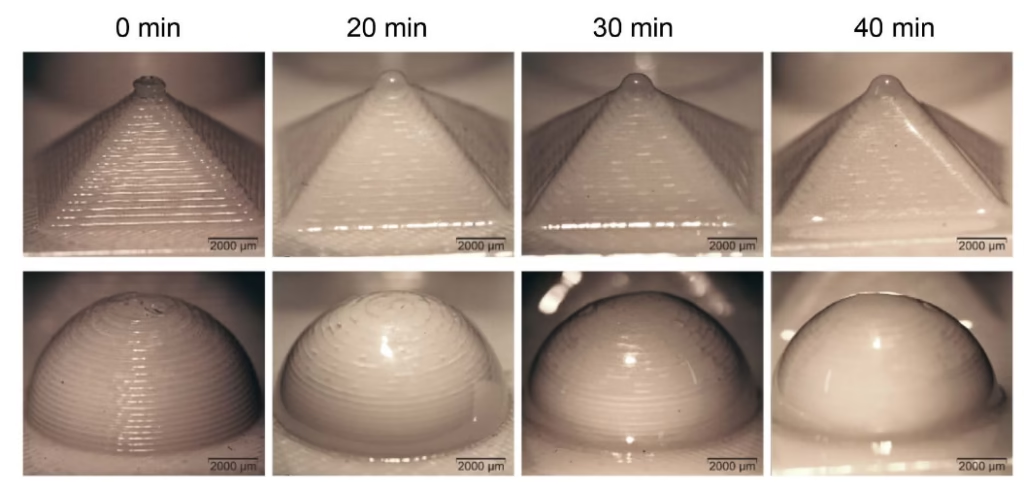

Experimental studies show that surface roughness (Ra) of ABS parts can be reduced by up to 90% after acetone vapor smoothing, particularly on flat surfaces . This reflow mechanism also explains why excessive exposure can cause rounding of sharp edges and dimensional deviation.

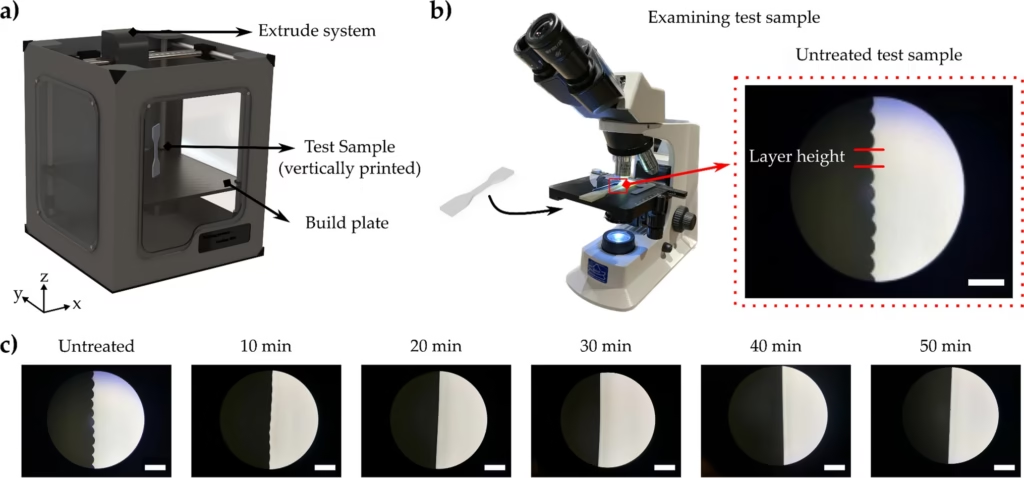

Industrial Vapor Smoothing vs DIY Setup

Industrial systems use:

- Controlled vapor concentration

- Enclosed, ventilated chambers

- Timed exposure cycles

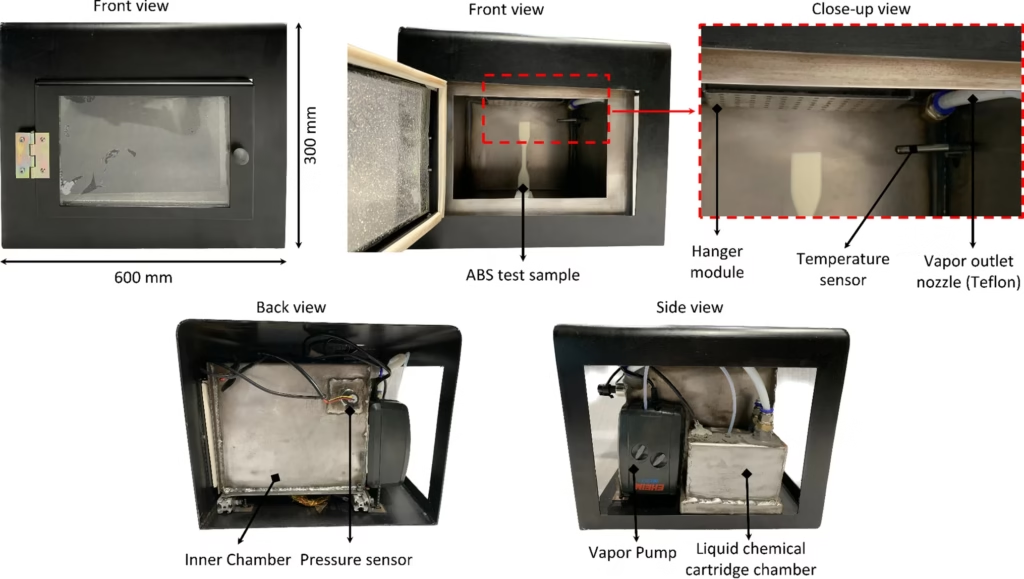

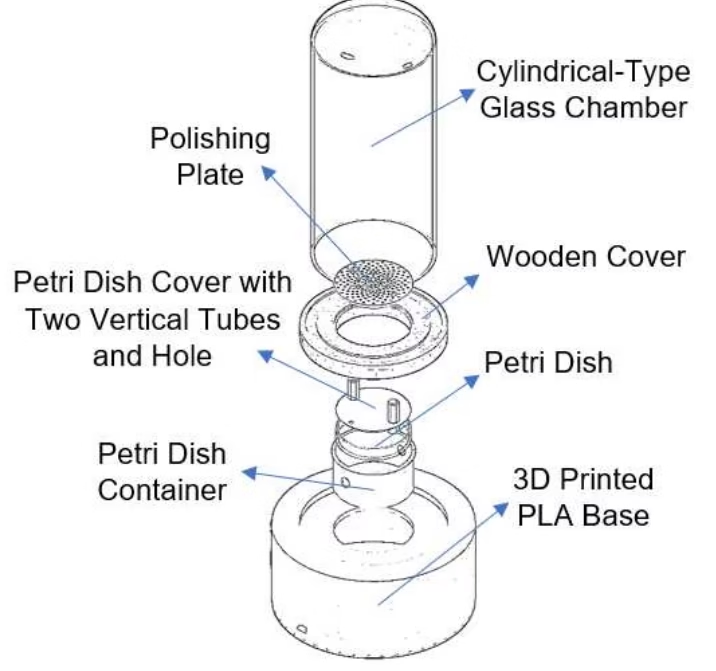

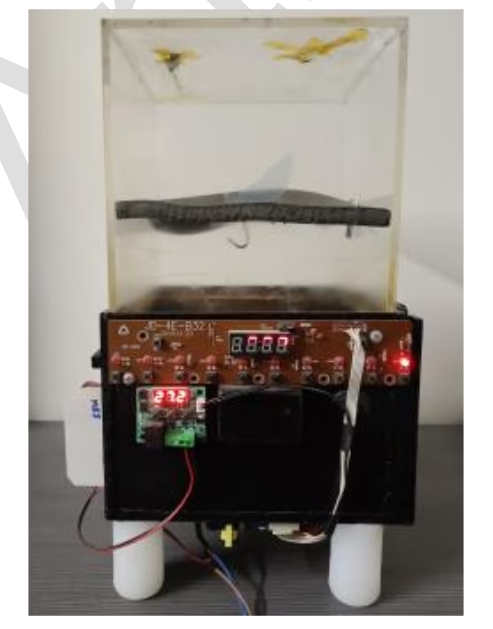

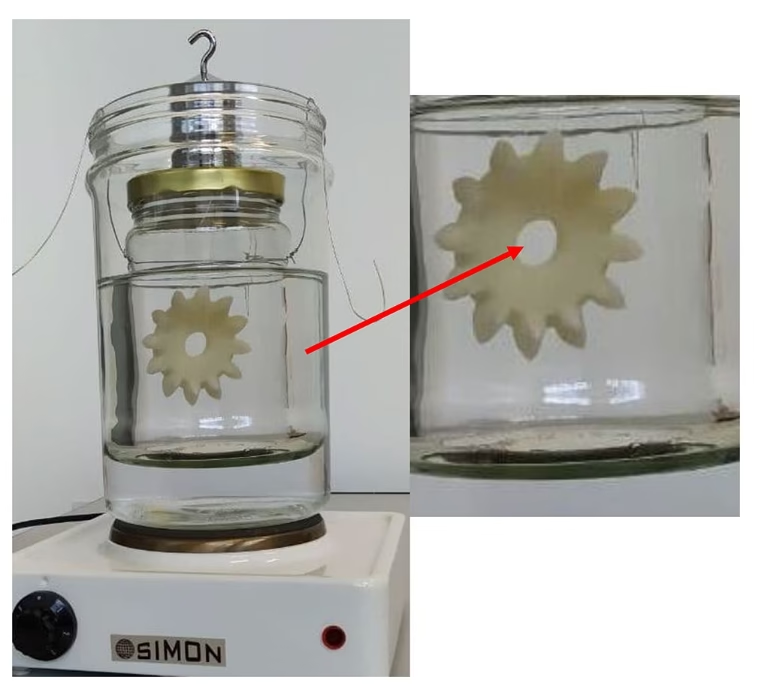

DIY vapor smoothing often involves improvised containers, vapor forming, pump which can produce inconsistent results and safety risks. Research comparing controlled devices versus improvised setups demonstrates that standardized vapor polishing devices significantly improve repeatability, surface uniformity, and operator safety .

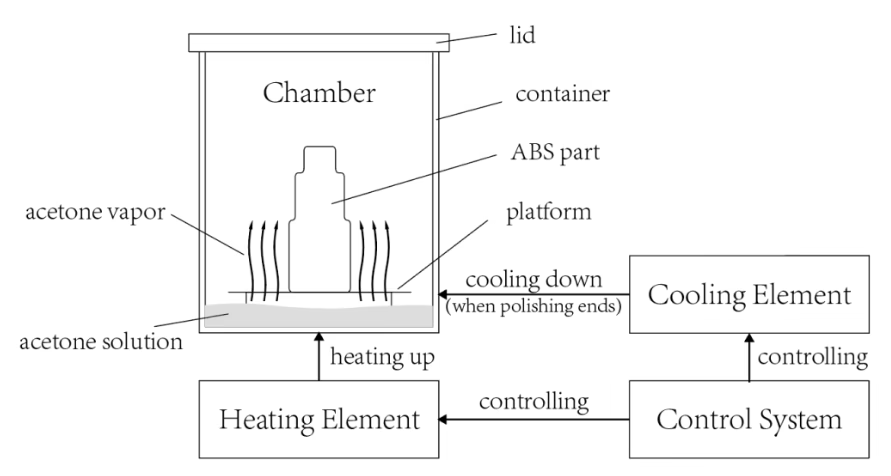

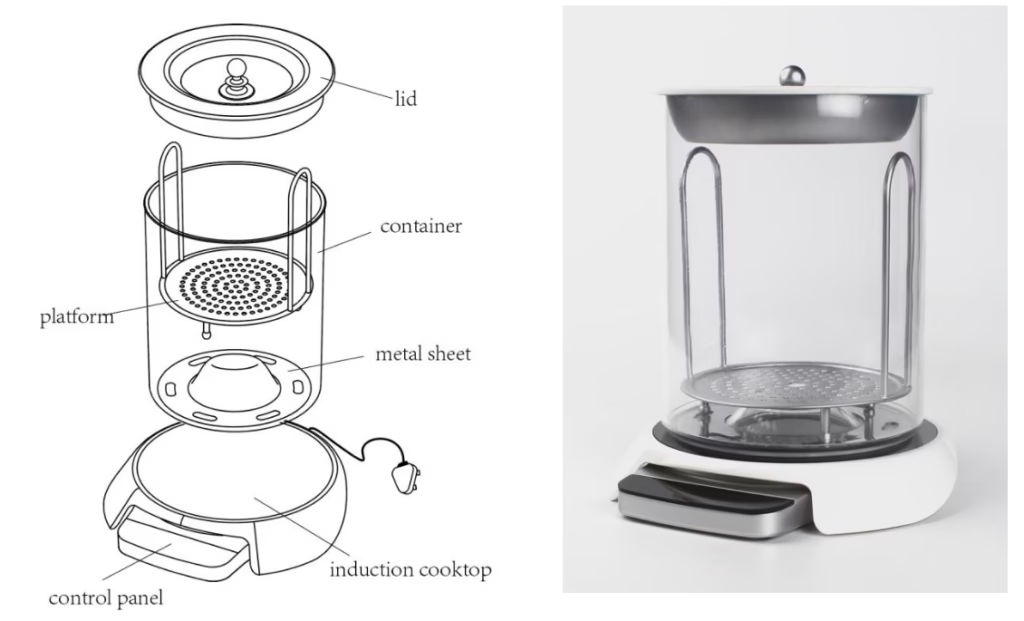

I am here attaching different DIY vapor smoothing or polishing system used in various research articles:

Acetone Vapor Smoothing Explained

What Is Acetone Vapor Smoothing?

Acetone vapor smoothing is a solvent-based finishing method primarily used for ABS 3D prints. Instead of immersing parts in liquid acetone, the print is exposed to acetone vapors inside a sealed chamber.

This method is preferred because:

- It provides uniform surface treatment

- It reduces excessive material removal

- It allows better control over dimensional accuracy

Why Acetone Works Best for ABS

ABS (Acrylonitrile Butadiene Styrene) contains butadiene rubber domains that readily interact with acetone. This compatibility allows acetone vapors to soften the surface without fully dissolving the bulk material. Multiple studies confirm that acetone vapor smoothing is highly effective for ABS, producing glossy surfaces and significantly reduced roughness .

Step-by-Step Acetone Vapor Smoothing Process

Vapor smoothing is an advanced post-processing technique developed by Stratasys Inc. in which heated solvent vapors, typically acetone, interact with the surface of FDM-printed parts to soften the outer layers, allowing surface reflow and improved layer fusion without affecting the bulk material.

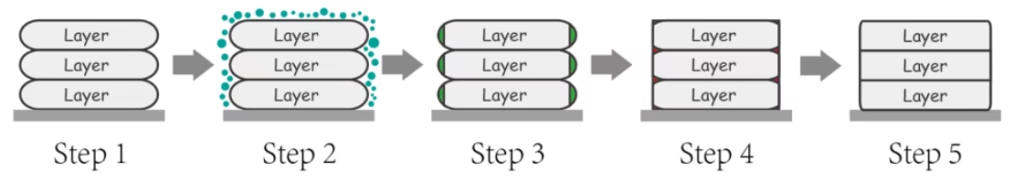

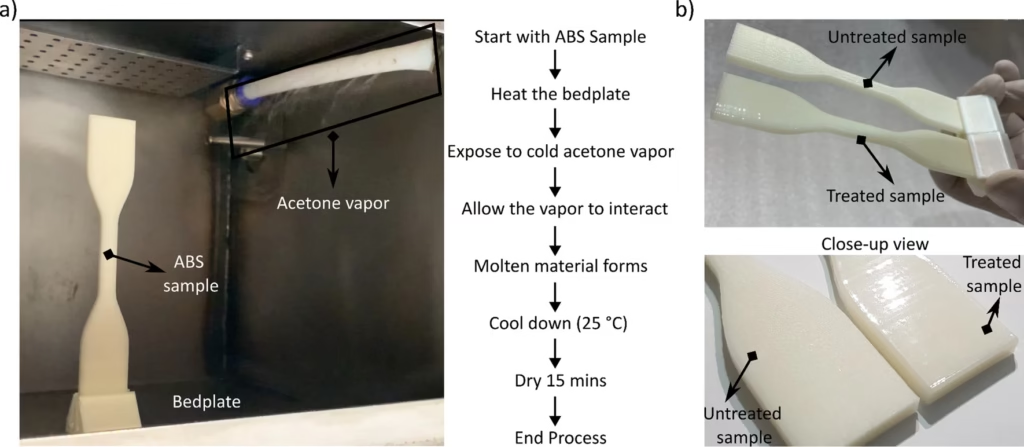

As illustrated in Figure 1, the vapor smoothing process can be described in five sequential stages:

- Initially, the as-printed acrylonitrile butadiene styrene (ABS) components exhibit relatively high surface roughness due to the layer-by-layer deposition inherent to FDM.

- Upon exposure to acetone vapor, the solvent begins to chemically interact with the outer surface of the ABS part.

- This interaction causes the surface material to enter a semi-molten or softened state, increasing polymer chain mobility.

- The softened polymer flows into the interlayer voids and surface irregularities, effectively reducing the staircase effect and flattening the surface topology.

- Finally, as the solvent evaporates and the surface resolidifies, a smooth and uniform finish is obtained, completing the vapor smoothing process.

Typical Results and Finish Quality

Observed results include:

- Up to 90% reduction in surface roughness

- Glossy, injection-mold-like finish

- Reduced surface porosity

- Rounded edges with excessive exposure

Best Materials for Vapor Smoothing 3D Printing

Vapor Smoothing ABS (Most Popular)

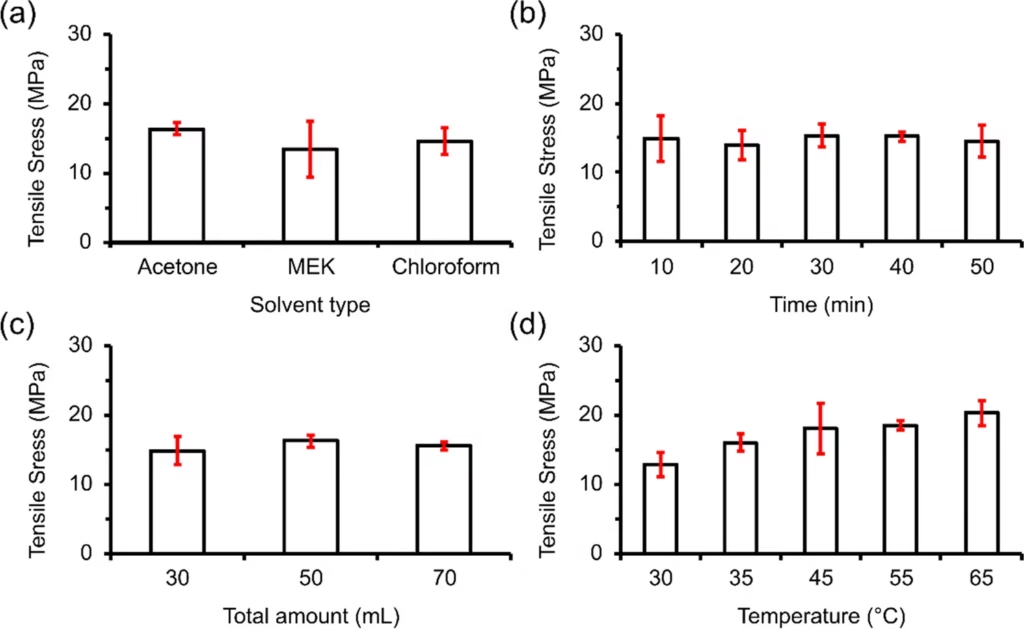

ABS is the most extensively studied material for vapor smoothing. Research consistently confirms:

- Significant roughness reduction

- Improved surface sealing

- Possible tensile strength improvement due to better layer fusion ( and )

ASA Vapor Smoothing

ASA behaves similarly to ABS but requires stricter process control. Industrial systems are preferred due to solvent handling requirements.

Nylon Vapor Smoothing (Industrial Only)

Nylon requires specialized solvents and controlled conditions. Studies indicate effectiveness but recommend industrial vapor smoothing systems only due to chemical hazards.

Why PLA Is Not Ideal for Vapor Smoothing

PLA does not respond to acetone. Alternative solvents such as ethyl acetate have been researched, achieving up to 85–90% roughness reduction under controlled conditions . However, PLA vapor smoothing is less forgiving and more sensitive to parameter variation.

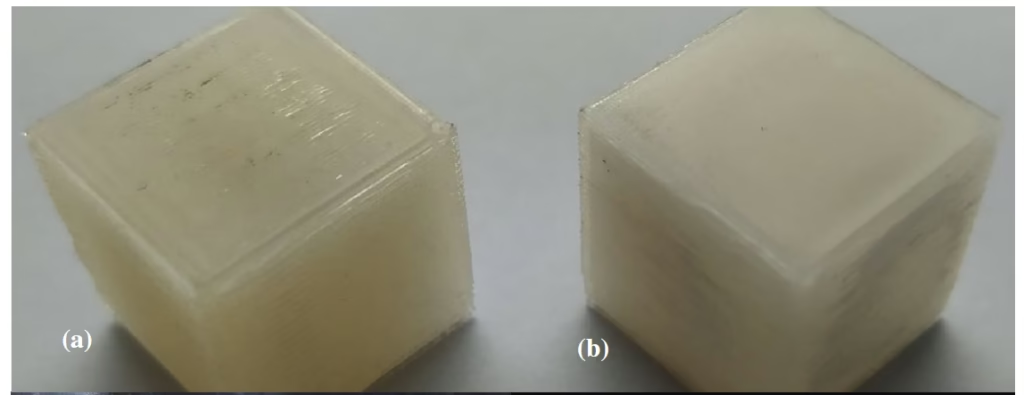

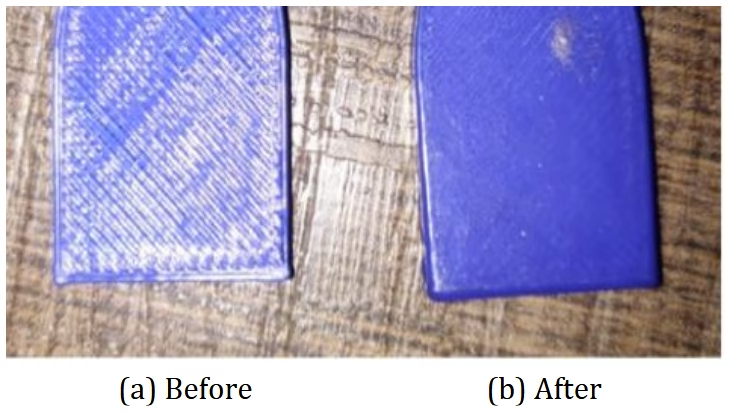

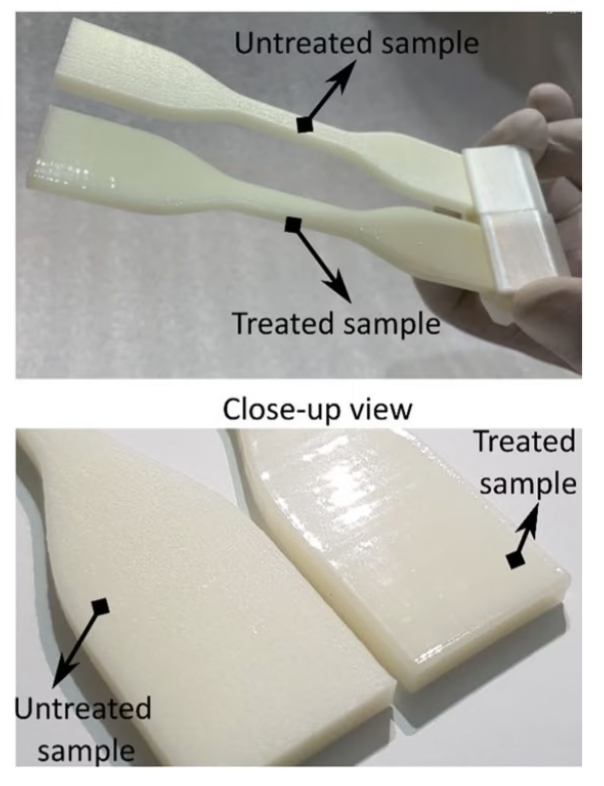

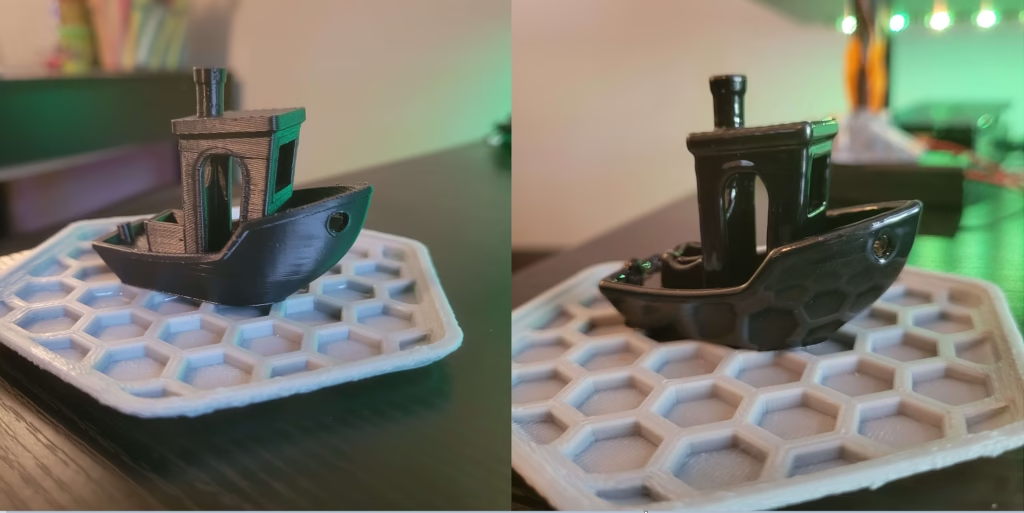

Benefits of Vapor Smoothing in 3D Printing

One of the biggest reasons vapor smoothing has gained popularity is its ability to transform the look and feel of a 3D-printed part without extensive manual effort. Unlike sanding or coating, vapor smoothing works at a material level, allowing the surface to reflow and self-level. The most noticeable improvement is in surface appearance. Layer lines caused by the staircase effect are significantly reduced, resulting in smooth, glossy surfaces that closely resemble injection-molded components. This is especially valuable when parts are meant to be seen, handled, or sold as finished products.

Beyond aesthetics, vapor smoothing also reduces surface roughness and closes micro-pores formed during FDM printing. This sealing effect is critical for parts exposed to moisture, chemicals, or repeated cleaning. As a result, vapor smoothing is widely used for medical components and fluid-contact parts, where surface hygiene and cleanability matter as much as appearance.

From a mechanical standpoint, studies on acetone-smoothed ABS parts show that vapor smoothing can enhance layer-to-layer bonding at the surface, which may lead to improvements in tensile strength and durability when exposure is properly controlled . Instead of weakening the part, the process can actually eliminate surface defects that act as stress concentrators. Overall, vapor smoothing gives 3D-printed parts a professional, production-ready finish, making it suitable not just for prototypes, but also for end-use components when applied correctly.

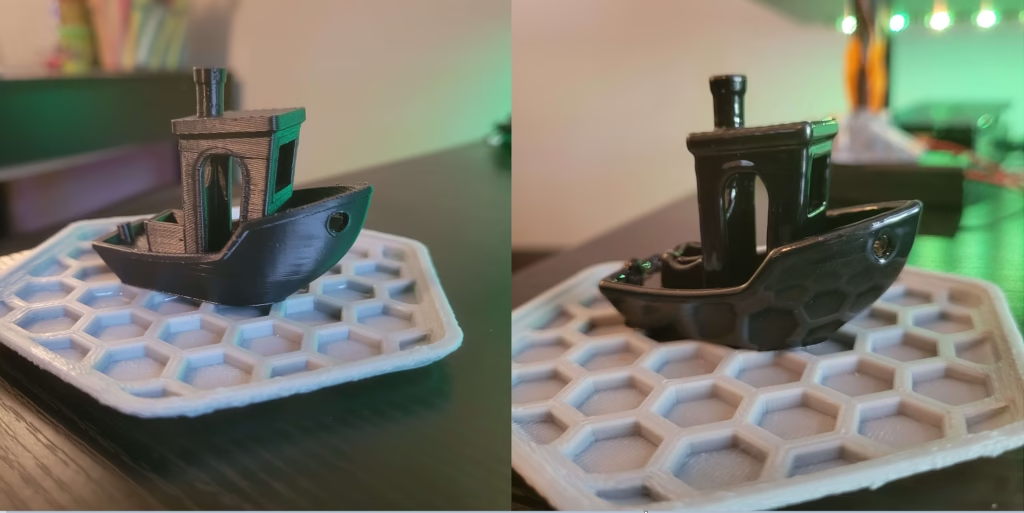

Below, I am providing before and after images of vapor smoothed/polished 3D printed parts found in various research articles and over the internet:

Other 3D Print Vapor Smoothing image from the internet

Safety Guidelines for Vapor Smoothing

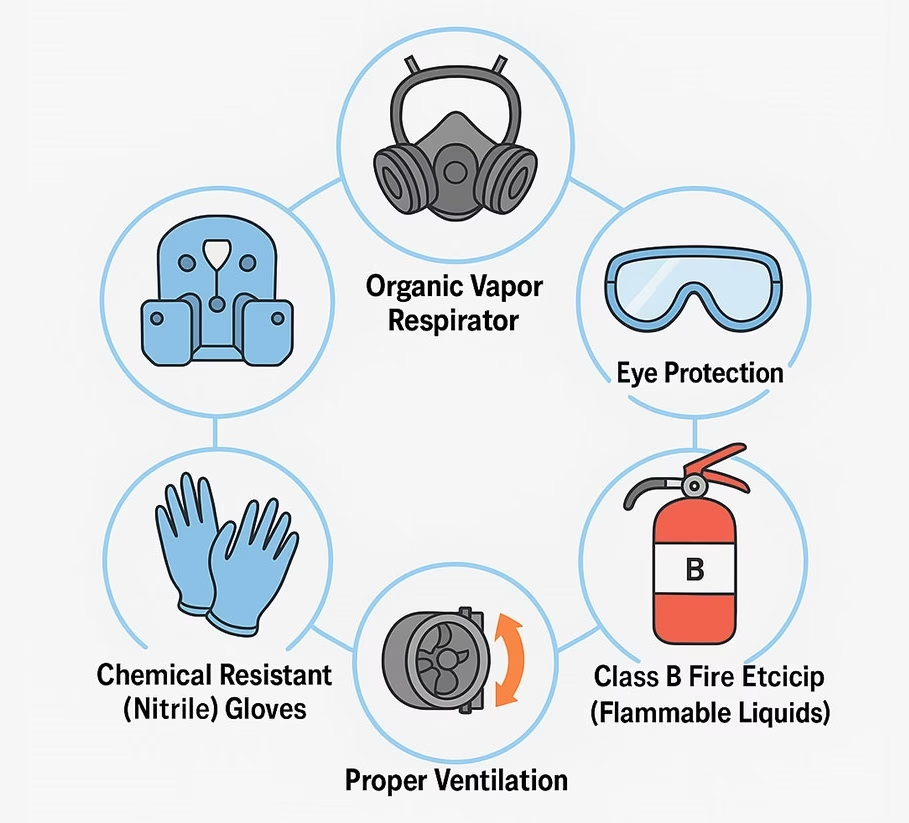

While vapor smoothing is highly effective, it must be treated as a chemical processing step, not a casual post-print activity. Most vapor smoothing processes—especially acetone vapor smoothing—use volatile solvents that can pose serious safety risks if handled improperly.

Chemical Hazards and Health Risks

Acetone vapors are highly flammable and can cause irritation, dizziness, or respiratory issues when inhaled in high concentrations. Prolonged or repeated exposure without protection increases health risks, particularly in poorly ventilated spaces.

Ventilation and Fire Safety

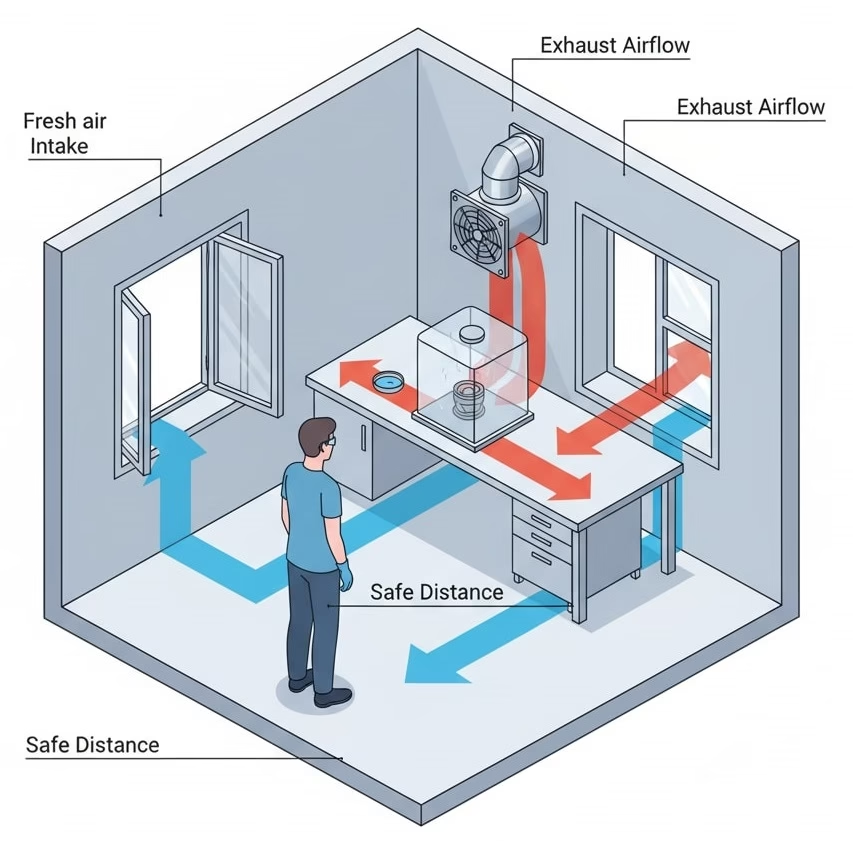

Research consistently emphasizes the importance of controlled environments for vapor smoothing. Safe setups rely on:

- Enclosed or sealed chambers

- Effective ventilation to prevent vapor buildup

- Strict elimination of ignition sources such as open flames, sparks, or heating elements

Improvised open containers or poorly sealed setups significantly increase the risk of fire and solvent exposure.

Personal Protective Equipment (PPE)

Anyone performing vapor smoothing should use appropriate PPE, including:

- Chemical-resistant gloves

- Safety goggles or face protection

- Respiratory protection when ventilation is insufficient

These precautions are standard in laboratory and industrial vapor polishing setups and should not be skipped.

Common Safety Mistakes to Avoid

Some of the most frequent causes of accidents include:

- Using open or unsealed containers

- Adding excessive solvent volume

- Leaving parts exposed for uncontrolled durations

Proper timing, containment, and handling are essential to safe vapor smoothing.

DIY Vapor Smoothing vs Professional Vapor Smoothing Service

Choosing between DIY vapor smoothing and a professional service depends largely on application, safety requirements, and quality expectations.

DIY Vapor Smoothing – Pros & Cons

DIY vapor smoothing is attractive because it is low cost and accessible, especially for hobbyists and early prototypes. However, these benefits come with clear drawbacks. DIY setups often suffer from inconsistent results, higher safety risks, and greater chances of dimensional distortion due to poor process control.

Professional Vapor Smoothing Service – Pros & Cons

Professional vapor smoothing services use purpose-built equipment, controlled vapor concentrations, and repeatable processing cycles. This results in consistent surface quality, better dimensional control, and significantly improved safety. The main downside is higher upfront cost, which may not be justified for one-off cosmetic prints.

When You Should Choose a Vapor Smoothing Service

For production parts, medical components, fluid-handling systems, or commercial products, research strongly supports the use of professional vapor smoothing services. In these cases, consistency, safety, and regulatory considerations outweigh the cost difference.

Cost of Vapor Smoothing in 3D Printing

The cost of vapor smoothing varies widely depending on whether it is done in-house or outsourced.

DIY Vapor Smoothing Cost Breakdown

At first glance, DIY vapor smoothing appears inexpensive. Acetone itself is low cost, and basic containers and PPE are relatively affordable. However, hidden costs often emerge in the form of:

- Failed or warped parts

- Reprints due to over-smoothing

- Safety equipment upgrades

These indirect costs are frequently underestimated.

Professional Vapor Smoothing Service Cost

Professional services typically price vapor smoothing based on:

- Part size and geometry

- Material type (ABS, ASA, nylon, etc.)

- Required surface finish quality

Although the per-part cost is higher, the reliability and repeatability often reduce overall production risk.

Factors That Affect Vapor Smoothing Pricing

Key pricing factors include exposure time, dimensional tolerance requirements, and batch size. Larger batches generally reduce cost per part, making professional services more economical for scaled production.

Vapor Smoothing vs Other Post-Processing Methods

| Method | Surface Quality | Dimensional Accuracy | Labor |

|---|---|---|---|

| Sanding | Moderate | High | High |

| Epoxy coating | High | Moderate | Medium |

| Painting | Cosmetic | High | Medium |

| Tumbling | Limited | High | Low |

| Vapor smoothing | Very high | Medium | Low |

Vapor smoothing stands out by offering excellent surface quality with minimal manual labor, though it requires careful control to maintain dimensional accuracy.

Industrial Applications of Vapor Smoothing

Vapor smoothing is widely adopted in industries where surface quality, hygiene, and consistency are critical. Common applications include:

- Medical and laboratory devices

- Automotive interior components

- Consumer electronics enclosures

- Fluid-handling and sealed systems

Research consistently identifies reduced surface porosity and improved cleanability as key reasons for industrial adoption.

Final Verdict – Is Vapor Smoothing Worth It?

Vapor smoothing is among the most effective post-processing techniques available for thermoplastic 3D-printed parts. When applied correctly, especially for ABS using acetone vapor, it delivers surface finishes that are difficult to achieve through mechanical methods alone.

That said, vapor smoothing is not a casual process. Safety, dimensional control, and material compatibility must always come first. For hobbyists, DIY vapor smoothing can be useful for visual prototypes. For professional, medical, or commercial applications, professional vapor smoothing services remain the safest and most reliable choice.

If this tutorial helped you, consider supporting TechKnowLab or registering for free resources.

Suggested Articles for Further Reading

If you are interested in improving surface quality, material performance, and post-processing reliability in 3D printing, you may find the following articles useful:

- 3D Print Stringing: Causes, Problems, and How to Fix It

- Stop Cleaning Your Nozzle: The Real Reason Long 3D Prints Fail (Heat Creep Explained)

- Resolving Filament Not Coming Out of 3D Printer – Complete Troubleshooting Guide

- DIY Smart RC Car Using Arduino and 3D Printing

- How 3D Printing Is Reshaping the Construction Industry

Frequently Asked Questions (FAQs)

Is vapor smoothing safe?

Vapor smoothing can be safe only when performed under controlled conditions. Research clearly shows that solvents like acetone are flammable and volatile, and improper handling can pose fire, inhalation, and chemical exposure risks .

Safe vapor smoothing requires:

Enclosed chambers

Adequate ventilation

No open flames or sparks

Proper personal protective equipment (PPE)

Because of these risks, academic studies strongly recommend standardized vapor polishing devices or professional vapor smoothing services instead of improvised DIY setups.

Can PLA be vapor smoothed?

PLA cannot be vapor smoothed using acetone. Acetone does not chemically interact with PLA.

However, research shows that PLA can be vapor smoothed using alternative solvents such as ethyl acetate, achieving surface roughness reductions of up to 85–90% under controlled conditions .

That said:

PLA vapor smoothing is more sensitive to time and solvent volume

Overexposure can easily deform parts

Industrial or laboratory setups are recommended

For most users, PLA is not ideal for vapor smoothing compared to ABS.

Does vapor smoothing weaken 3D printed parts?

Not necessarily. In fact, multiple experimental studies report that acetone vapor smoothing of ABS can improve tensile strength.

This improvement occurs because softened polymer layers flow into inter-layer voids, increasing layer-to-layer adhesion and reducing stress concentration points.

However:

Excessive exposure can reduce dimensional accuracy

Mechanical benefits depend on exposure time and geometry

Properly controlled vapor smoothing does not weaken ABS prints and may enhance certain mechanical properties.

How long does acetone vapor smoothing take?

Yes—but only with industrial or professional vapor smoothing systems.

Vapor smoothing is widely used in production for:

-Medical components

-Fluid-handling parts

-Automotive interior components

-Consumer electronics enclosures

Research confirms that vapor smoothing can:

-Seal surface porosity

-Improve hygiene

-Enhance aesthetics

-Maintain acceptable dimensional accuracy when controlled properly

For commercial use, professional vapor smoothing services are strongly recommended.