3D Printing Top Layer Problems: Holes and gaps in the top layers of 3D prints can be frustrating and can compromise the overall quality of your printed object. Fortunately, there are several techniques you can use to fix these issues.

3D Printing Top Layer Problems

To improve the appearance of your 3D prints and address issues like gaps, holes, and bumps on the top layer, adjust settings in your 3D printing software. Increase layer count to fill gaps and enhance print solidity, or modify infill settings. Address plastic quantity issues if necessary. Consider using default settings for gap correction. Improve the top layer by adjusting thickness and employing ironing techniques, effectively addressing issues such as holes and bumps.

What is Pillowing?

If your 3D prints show unevenness, roughness, and holes on the top layer, it’s called pillowing. Pillowing is a noticeable defect that occurs at the end of the printing process. In simple terms, it causes the top layers of your prints to be ragged, open, uneven, and bumpy. It can be a hassle, especially after a long print.

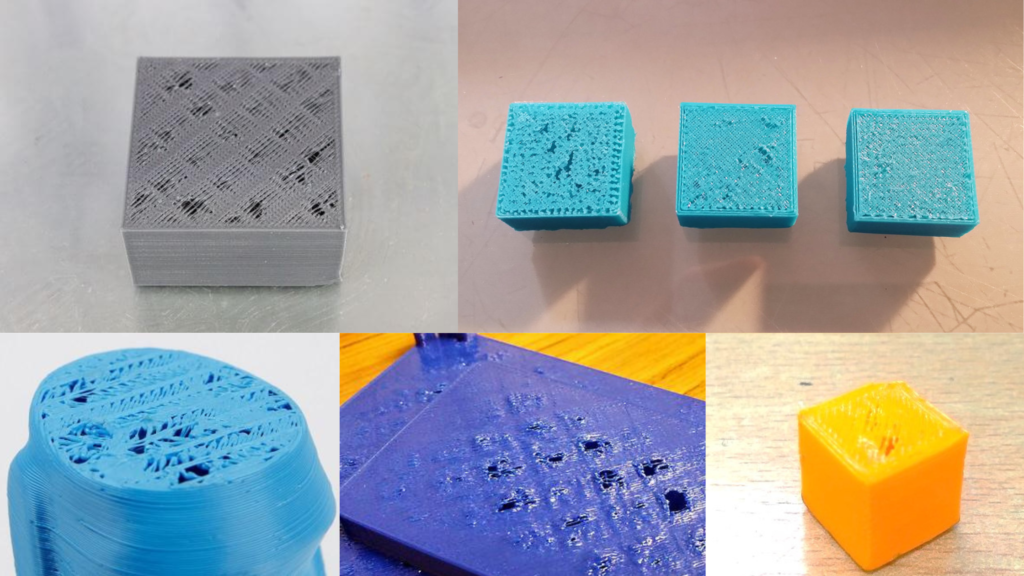

How Pillowing Looks Like?

Here are some images showing top layer problems (pillowing) in 3D printed parts:

Reasons for Pillowing or Top Layer Problems

There are primarily two reasons for pillowing or top layer problems:

- Insufficient Cooling – It causes the filament to warp away from the infill up towards the nozzle then it cools there and causes this effect. This occurs as a result of the material becoming tightened, sticking to the infill yet warping over the gaps beneath. Your layer cooling fans may also be at fault if they aren’t powerful enough to raise the material’s temperature to prevent this. Your materials could not have enough time to cool properly if you print too fast, which would lead to the same outcomes.

- Insufficient top layers – Additionally, pillowing can happen more easily if your prints don’t have enough solid top layers.

Filaments and Printers Susceptible to Pillowing

Any filament and any printer can experience pillowing (top layer problems), but some are much more susceptible. When we are printing with small layer heights, the filament warps more easily, and top layer problems are seen. Pillowing is more susceptible in printers that take in 1.75-mm filament than printers that use 2.85-mm. Apart from these softer filaments like TPU and higher temperature filaments such as ABS and polycarbonate are often more affected by the top layer problems (pillowing).

How to Cure Pillowing in 3D print

There are various solutions for pillowing (top layer problems), as there are for most printing issues. The best approach to fixing the issue is to combine several of the following techniques.

- Increase top layers – Although improper cooling can result in pillowing, a thin top surface is the main cause of this problem. Fortunately, this can be fixed quickly. Just increase the slicer’s top thickness up to six layers thick—six times the layer height—in the slicer. This ought to be plenty to hide any pillowing that takes place.

- Adjust cooling – Better cooling is required if pillowing is still happening. Make sure the cooling fans are turned on and running while the top layers are being printed. If so, the fans might not be designed to effectively chill your prints. A desk fan or other similar device may also be helpful, and there are several mods for this issue available online.

- Other Solutions – Pillowing can be lessened by lowering the print temperature, lowering the printing speed, and using more infill. However, because they can result in other issues, these solutions ought to only be used as a last resort.